asu fiber cable span 80 100 120

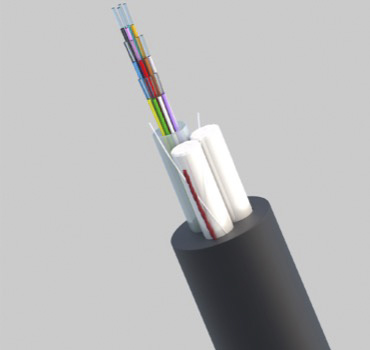

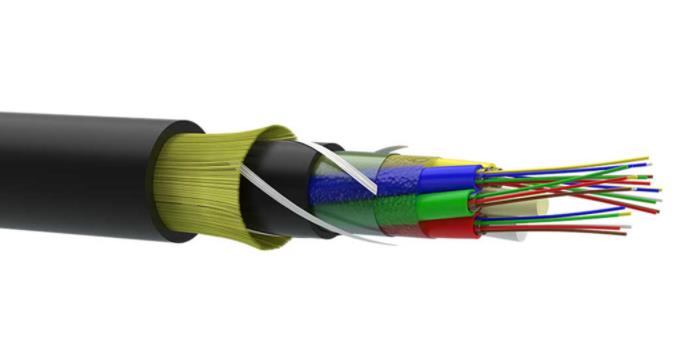

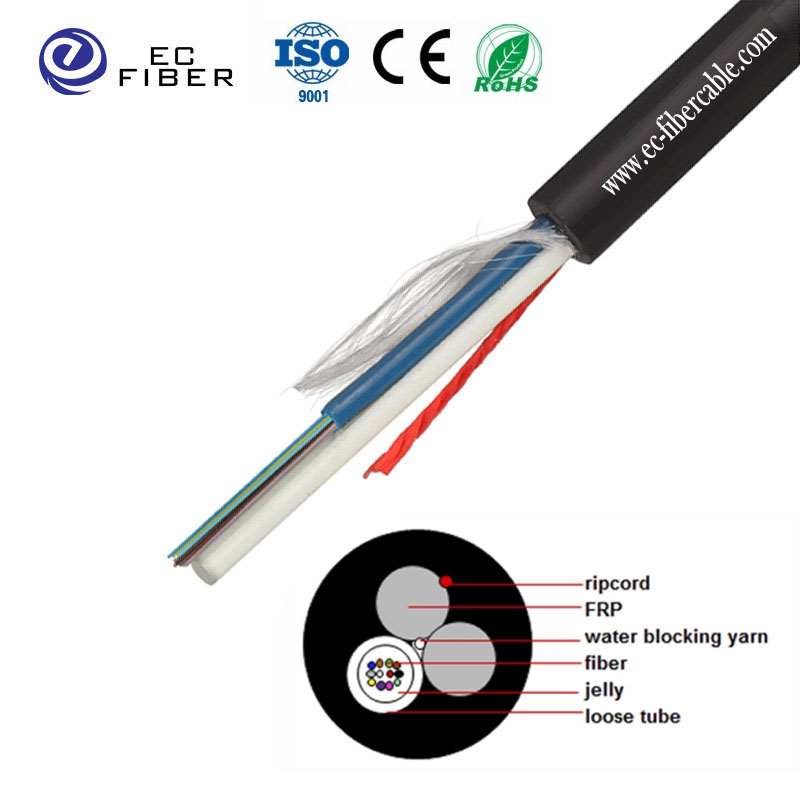

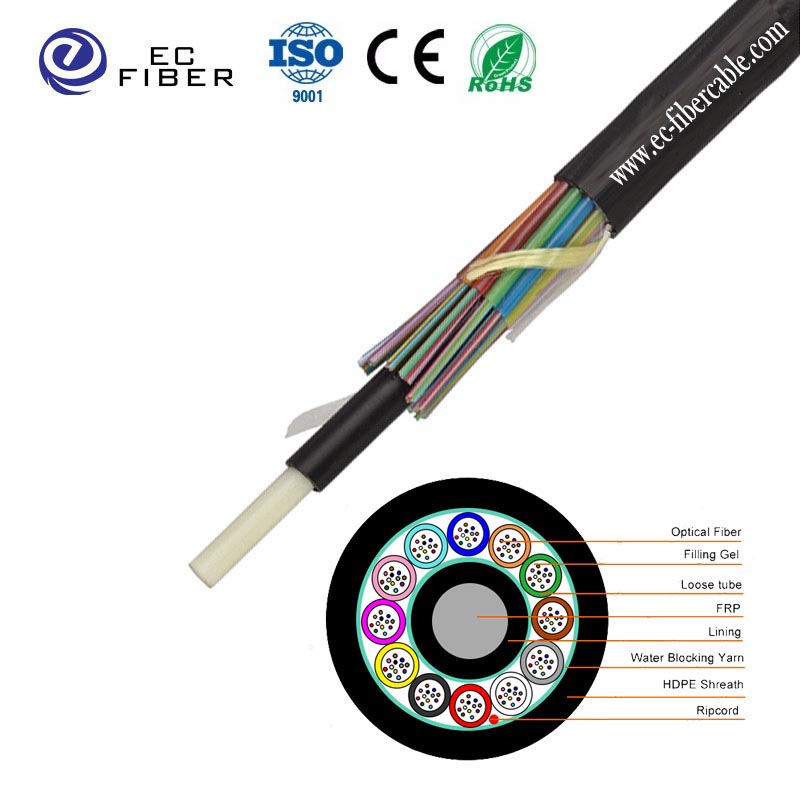

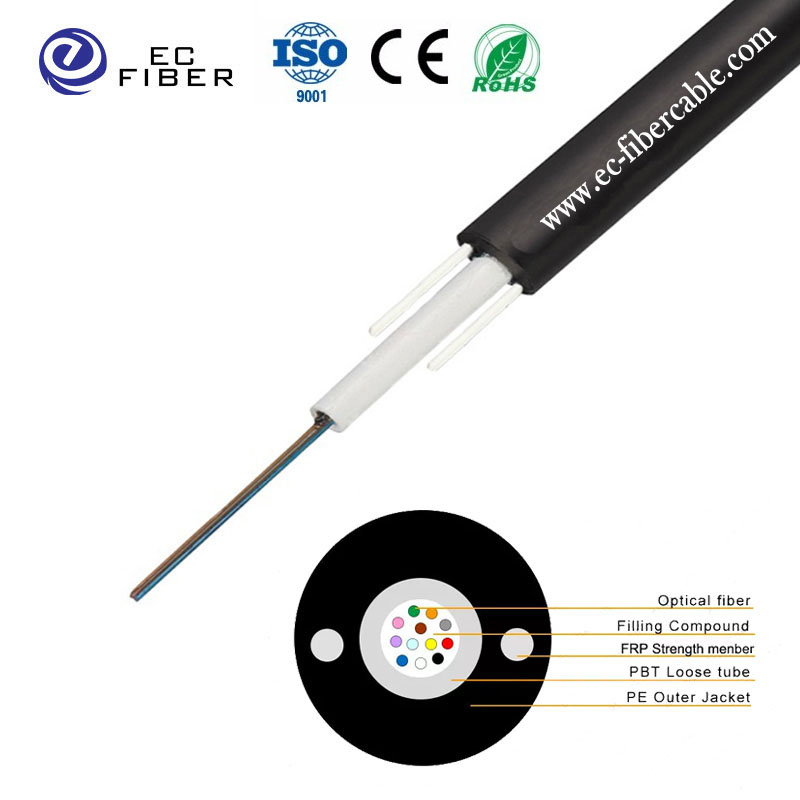

ASU fiber cable is typically designed for aerial deployment and is suitable for a range of spans, including 80, 100, and 120 meters. The specific span capabilities of the cable may vary depending on the manufacturer and the design. ASU fiber cables can come in various fiber count options, ranging fr...

Choose us is to choose high quality, we are your trust choice!

Choose us is to choose high quality, we are your trust choice!